The inventory fluctuates with every Purchase and Sales transaction. Knowing the exact status in real-time is the need of every business, to acquire a lead in the competitive market. An incorrect inventory position poses a potential commercial risk. Hence, monitoring the inventory is vital to manage the demand and supply.

We understand the problem statement of the business involving supply chain and e-commerce which demands the following:

- Real-time visibility of Inventory

- Integrated and Automated Systems

- Reducing multiple systems (Reducing TCO)

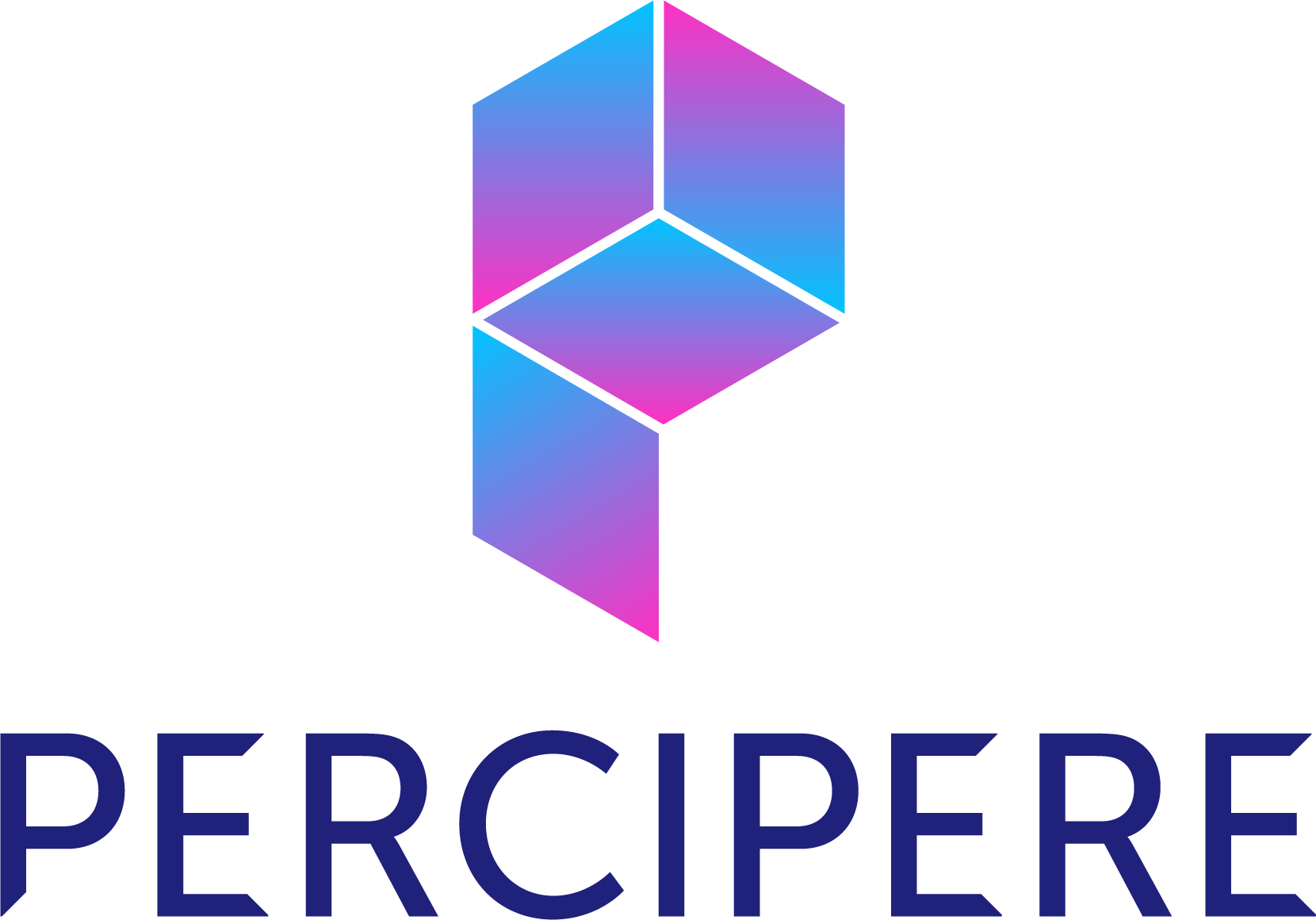

In the quest to solving the problem statement, Percipere developed a Scanning application native to SAP. It leverages the SAP’s UI5 technology and harnesses the S/4HANA capabilities. The solution is a bolt on to SAP S/4HANA and eliminates the need for additional hardware procurement. Access the custom scanning application via the SAP Fiori client that is platform agnostic and responsive to any form factor and is device independent so that you can use it on a mobile (Android, IOS, Windows), IPAD, Laptop or Desktop.

Key features:

- Natively built on SAP

- No additional hardware required (no need to procure barcode scanners)

- Works on any mobile device (Android, IOS, Windows)

- Plug and play

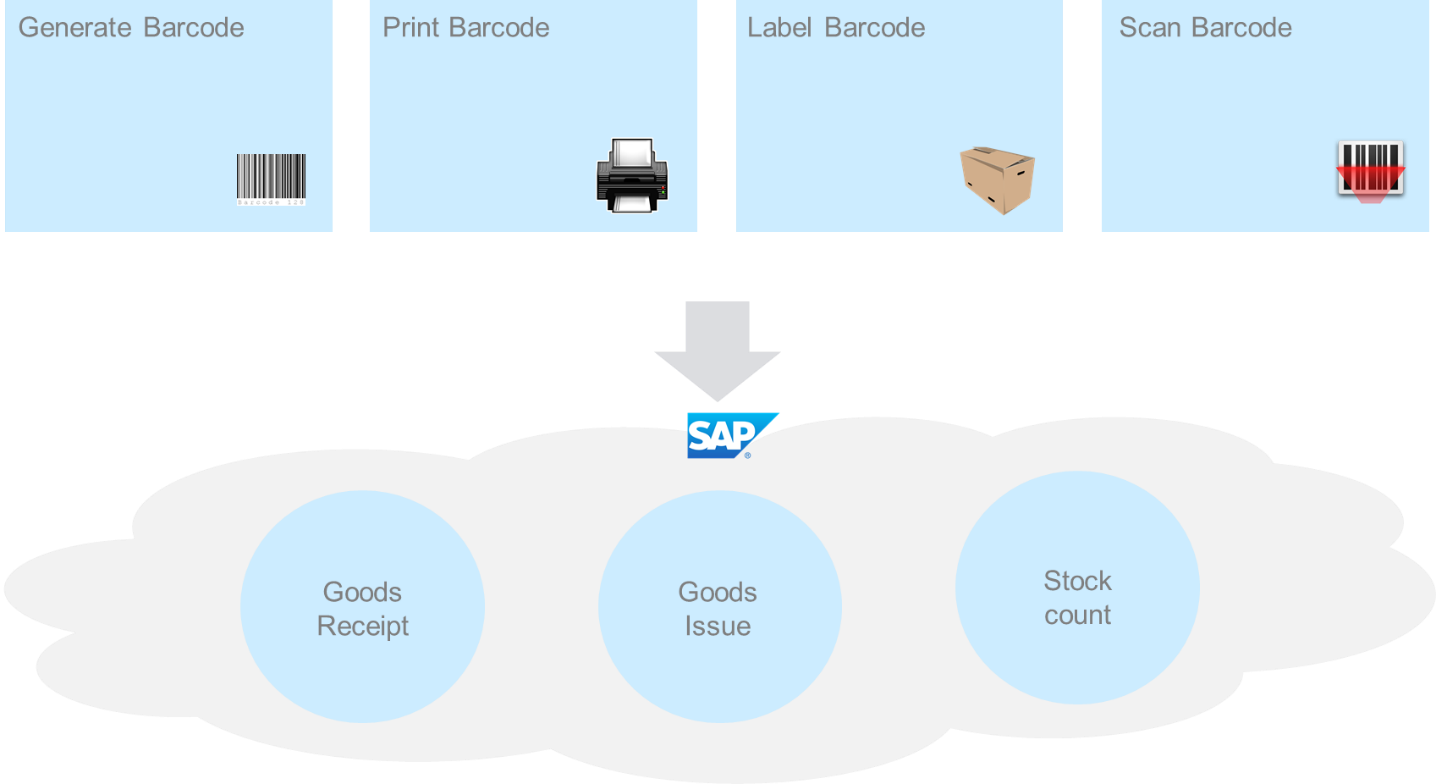

Access the Percipere Scan Desk application for inventory transactions in two simple steps.

- Download the SAP Fiori client

- Enter the Percipere Scan Desk link and SAP credentials that will navigate to the Scan Desk application

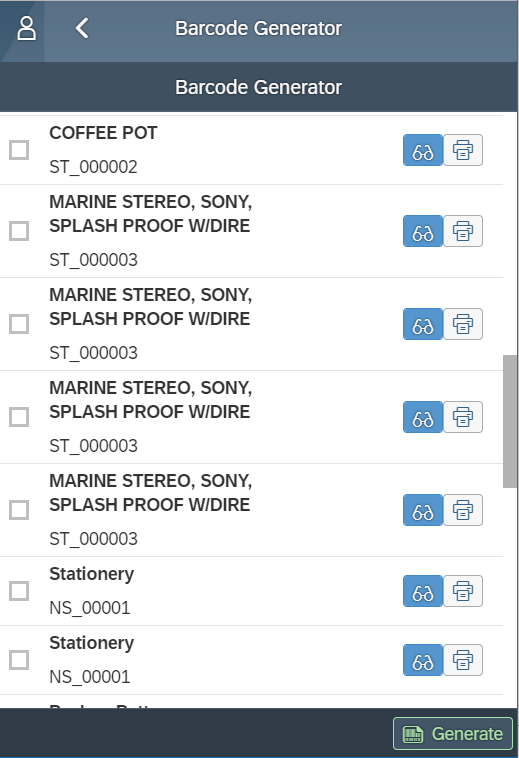

Barcode Generation

Generate the barcode In-house or let your supplier provide it. The barcode is recognized and decoded by the application to deposit the correct inventory count in SAP. It is customizable so that you can embed the level of details required by the organization. The lowest level detail can be the Purchase order and its line items that facilitate the Goods receipts with minimal manual intervention.

As a principle, the lesser the data entry required, the quicker are the inventory transactions. Ex. If the Barcode embeds details like Material, Plant, Storage location, PO, Line item, then while doing the receipt of the goods all these details are inherited from the Barcode itself, without the need to enter these details manually. Thus, implies minimal data entry and instant transaction processing.

Barcode Printing

An ordinary printer is sufficient to print the barcode, requires Time calibration on the pre-defined label sizes, and can do so automatically or manually.

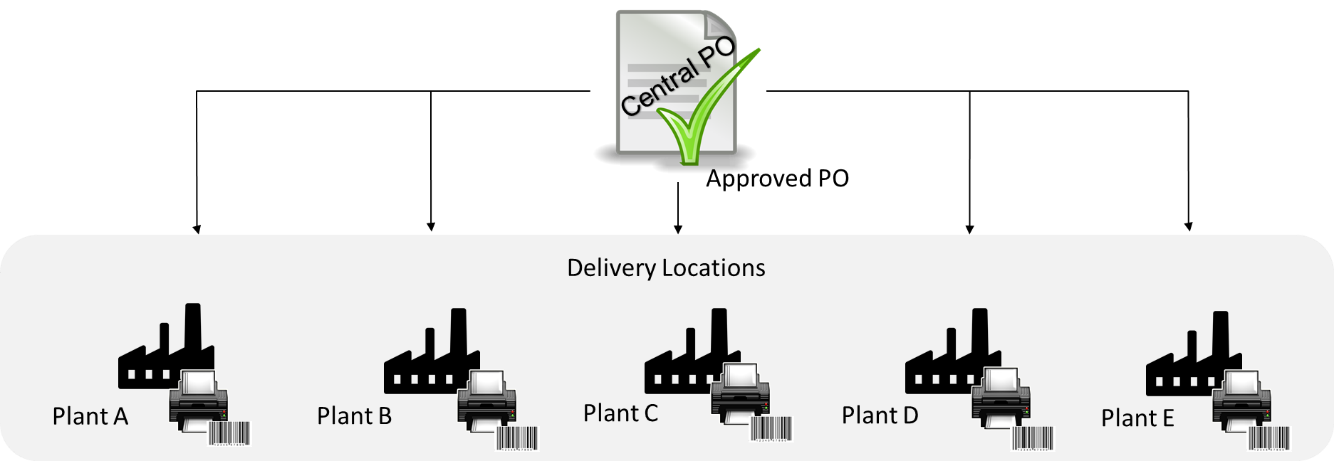

Automatic Printing of Barcodes

- Once the last level approving authority approves the PO, this action can trigger automatic printing.

- The central procurement creates PO and delivers goods to other locations. For this association, the respective branches can be intimated few days before the expected delivery date to facilitate the printing of barcodes.

The calibrated printers must be available at respective locations to print the barcode.

The barcodes can be printed on a need basis as well, using the Barcode generator App.

Conventional Goods Receipt

Goods receipt can be a painful exercise for a storekeeper with a heavy influx of goods into a warehouse. It is a practical challenge to identify the actual Purchase Orders from the humongous list of delivered goods. It is mandatory to acknowledge the receipt of the goods against a purchase order for the closure of the PO and managing supplier payments.

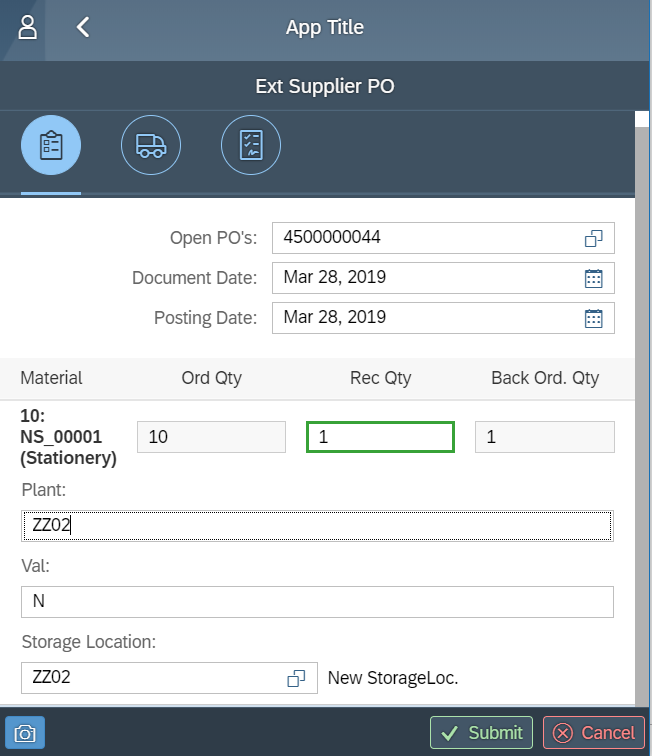

The Percipere Advantage – Goods Receipt

Scan your goods as they are delivered and let the “Goods Receipt” application do the recognition for you. After scanning the goods, the system can identify the material, plant, supplier, purchase order number, the line item on the PO and post the receipt of the goods. The SAP can generate the real-time financial document and receipt of goods (material movement) document. It eliminates the incorrect goods receipting to 99%, as the barcode has PO details embedded in it. Thus, the stock is recognized in the SAP System just by scanning the material on the mobile device.

In the view of making the goods receipt application user friendly, we have been able to achieve the following:

- Display all the relevant information on a single screen

- Minimize the data entry and derive most of the information from the Barcode & PO

- Minimize the number of clicks to complete the transactions

Goods Issue:

The conventional goods issue demands the manual entry of Material, Plant, Storage Location quantity and Document dates.

The account assignment needs to be entered manually depending on the nature of the goods issue or moment type. In case of multiple goods issue, re-enter the records manually for each item.

The Percipere Advantage – Goods Issue

Scan the materials to be issued. The details like Plant, Storage location, are derived from the Barcode. Quantity can be entered manually or in increments with every scan. Derive the account assignment by way of a mapping table. Each new material scan generates a new line item and derives the details automatically, thus reducing a significant amount of time and eliminating the data entry errors.

A real-time goods receipt document (material movement) and the financial document is generated in SAP, updating the inventory movements in real-time.

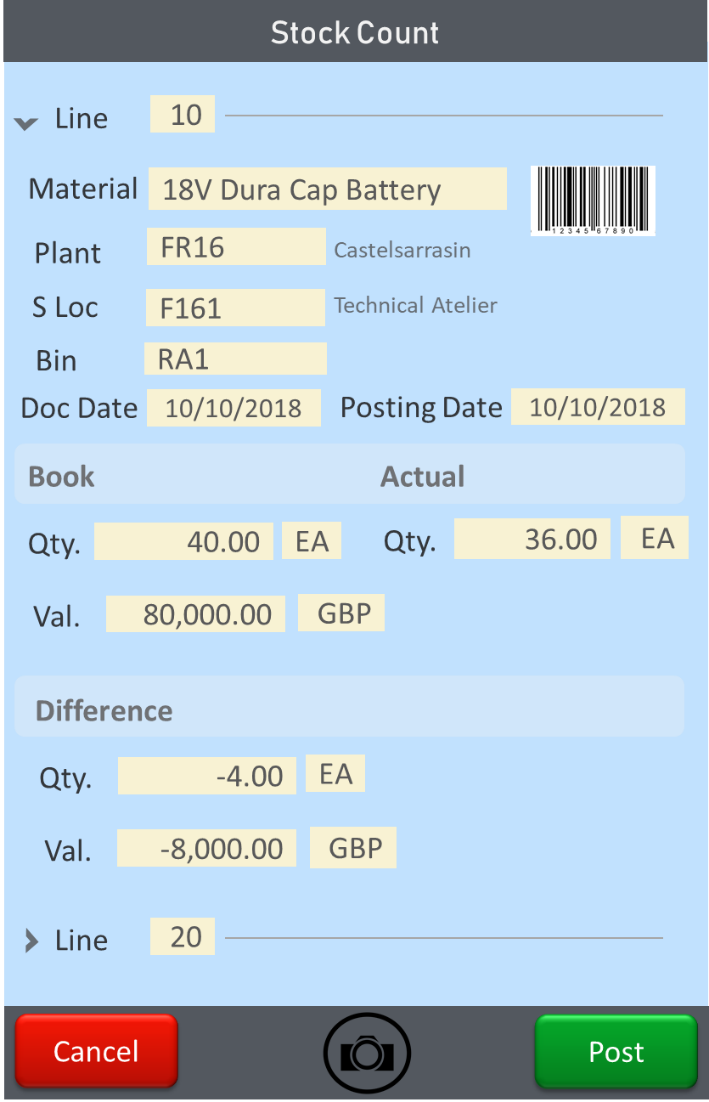

Stock Count

The stock count can be one cumbersome exercise for reconciling the actual and book inventory counts. In SAP, it’s a multi-step process that includes the following:

- Create physical document

- Count the inventory

- Update the count in the document

- Compare the physical and book count

- Post the difference

This process demands the manual counting of the inventory materials, which can go on for few days for large organizations.

The Percipere Advantage – Stock Count

Scan the materials to derive the actual count, and the system shall derive the book count on the fly. The comparison report generated in real-time provides the difference between the Actual quantity v/s Book quantity and the differential value. You can post the inventory correction value from the same screen. Essentially that would eliminate the five steps of the conventional stock count.

Business benefits

- Reduced TCO as the solution is native to SAP and no additional hardware required for scanning

- Get real-time inventory status and financial reporting

- Eliminate data entry errors, increase operational efficiency

- Manage demand-supply efficiently

By using the Inventory scanning application, you can streamline your supply chain. It can deliver exceptional results that will help you to reduce costs and boost productivity and at the same time meet your customer demands.

Author: Abhay Mehta, SAP S/4HANA Public Cloud Consultant